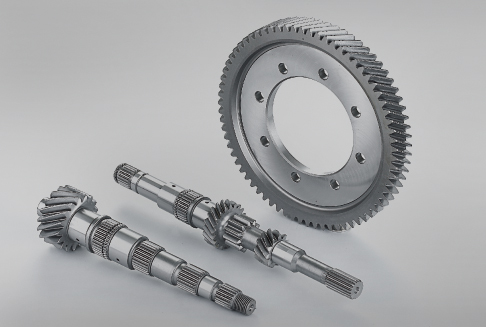

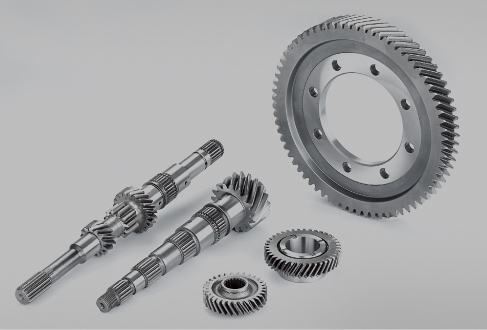

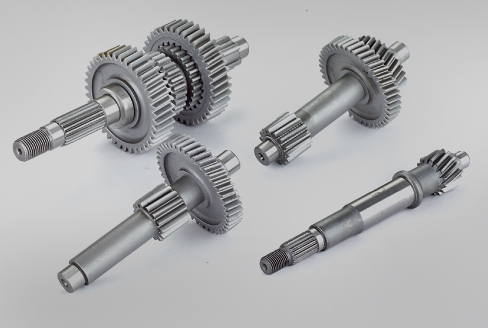

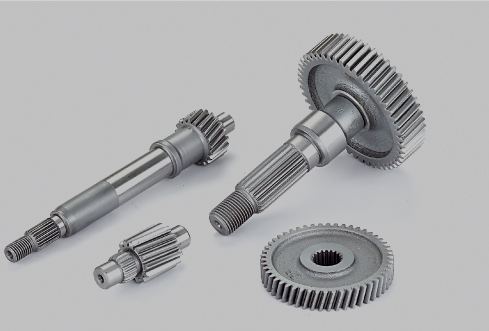

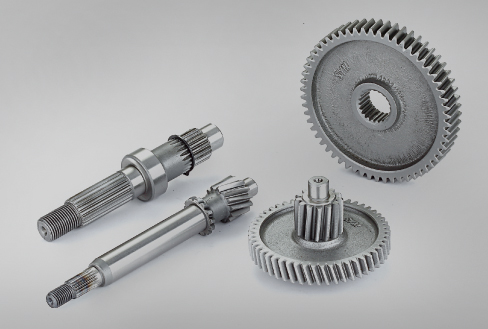

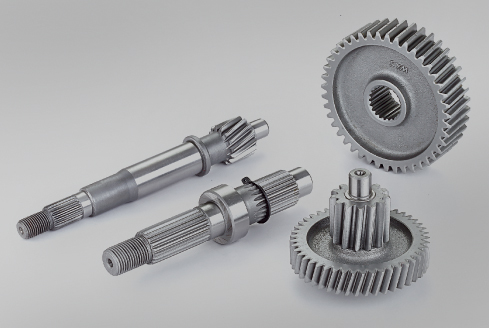

Professional manufacturer of automobile transmission gears, mechanical engineering gears, engine gears, light and heavy trucks, and truck transmission gears.

What Factors Should Be Considered in the Design of Light Truck Gears

The light truck gear system is a crucial component in light trucks, responsible for transmitting the power generated by the engine to the wheels, thereby driving the vehicle. An efficient and reliable light truck gear system is of great significance for improving vehicle performance, reducing fuel consumption, and ensuring driving safety. Therefore, the design of the light truck gear system needs to comprehensively consider multiple factors to meet the requirements under different working conditions.

When designing a light truck gear system, the good consideration is the selection of gear materials. In order to ensure that gears have sufficient strength and wear resistance when subjected to large loads and high-speed operation, light truck gear systems are usually made of high-strength and wear-resistant materials, such as alloy steel, powder metallurgy, etc. These materials can not only improve the load-bearing capacity of gears, but also extend their service life.

In addition to material selection, the design of light truck gear systems also needs to focus on optimizing the gear structure. In order to improve transmission efficiency, reduce noise, and reduce gear size, light truck gear systems usually use structures such as spiral gears or hyperbolic gears. These structures can effectively reduce friction losses between gears, improve transmission efficiency, and thus reduce fuel consumption.

The lubrication of the light truck gear system is also a key concern in the design process. Gears generate friction and heat during high-speed operation. Proper lubrication can reduce gear friction, dissipate heat, and protect gears. The light truck gear system requires the use of specialized gear oil for lubrication, which has high viscosity and wear resistance, ensuring the normal operation of the gears and extending their service life.

When designing a light truck gear system, it is also necessary to consider the maintenance and upkeep of the system. Due to the various complex working conditions that light trucks may encounter during daily use, the gear system of light trucks may experience problems such as wear and damage. In order to ensure the performance and safety of vehicles, consideration should be given to how to facilitate regular inspections and maintenance by car owners, and timely replacement of worn gears and lubricating oil during design.

The design of the light truck gear system also needs to fully consider the vehicle's load-bearing capacity and power output. In the design process, it is necessary to reasonably select parameters such as gear size, modulus, and number of teeth based on the specific application scenarios and usage needs of the vehicle. The selection of these parameters will directly affect the transmission efficiency and load-bearing capacity of the light truck gear system, thereby affecting the performance and fuel economy of the vehicle.

In addition, the design of the light truck gear system also needs to focus on driving comfort. In order to reduce noise and vibration, and improve the driver's driving experience, the design of the light truck gear system should minimize the clearance and impact between the gears as much as possible. This can be achieved by optimizing the geometric shape of gears, adopting high-precision machining techniques, and using shock-absorbing materials.

The design of a light truck gear system is a complex and important process that requires comprehensive consideration of various factors such as materials, structure, lubrication, and maintenance. By optimizing the design of the light truck gear system, the performance of light trucks can be improved, fuel consumption can be reduced, and service life can be extended, providing users with a better driving experience.

简体中文

简体中文 English

English España

España Русский язык

Русский язык